CAPTIVE WINCH SAFETY CHECKS

AND SERVICE

Scroll Down

CAPTIVE WINCH SAFETY INSPECTION / SERVICE

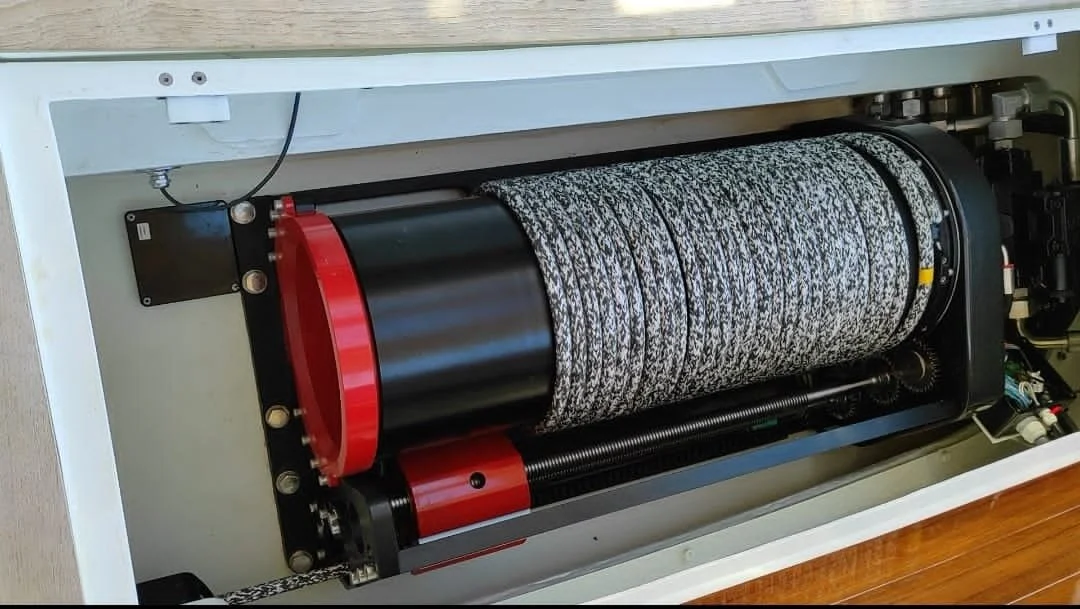

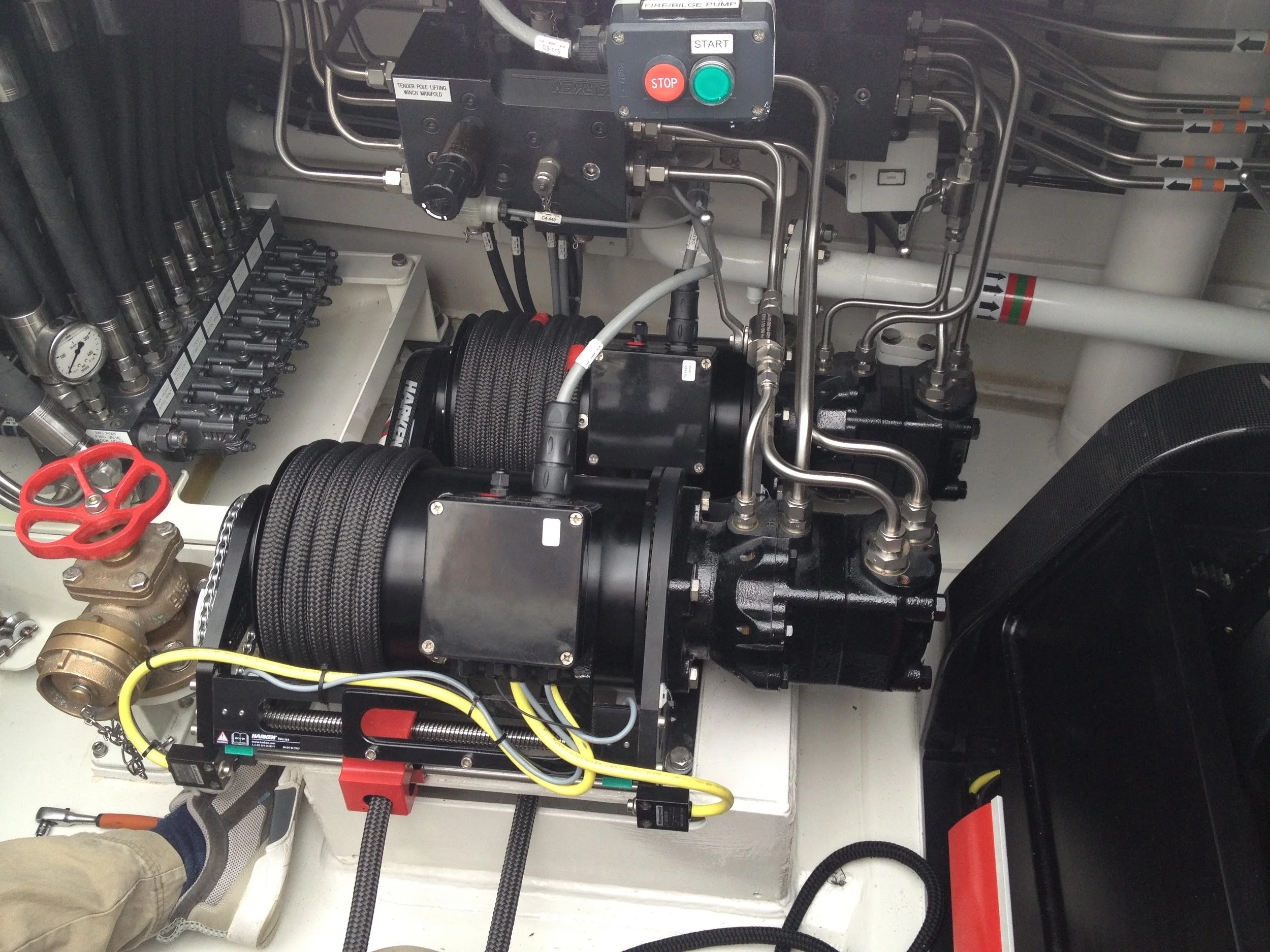

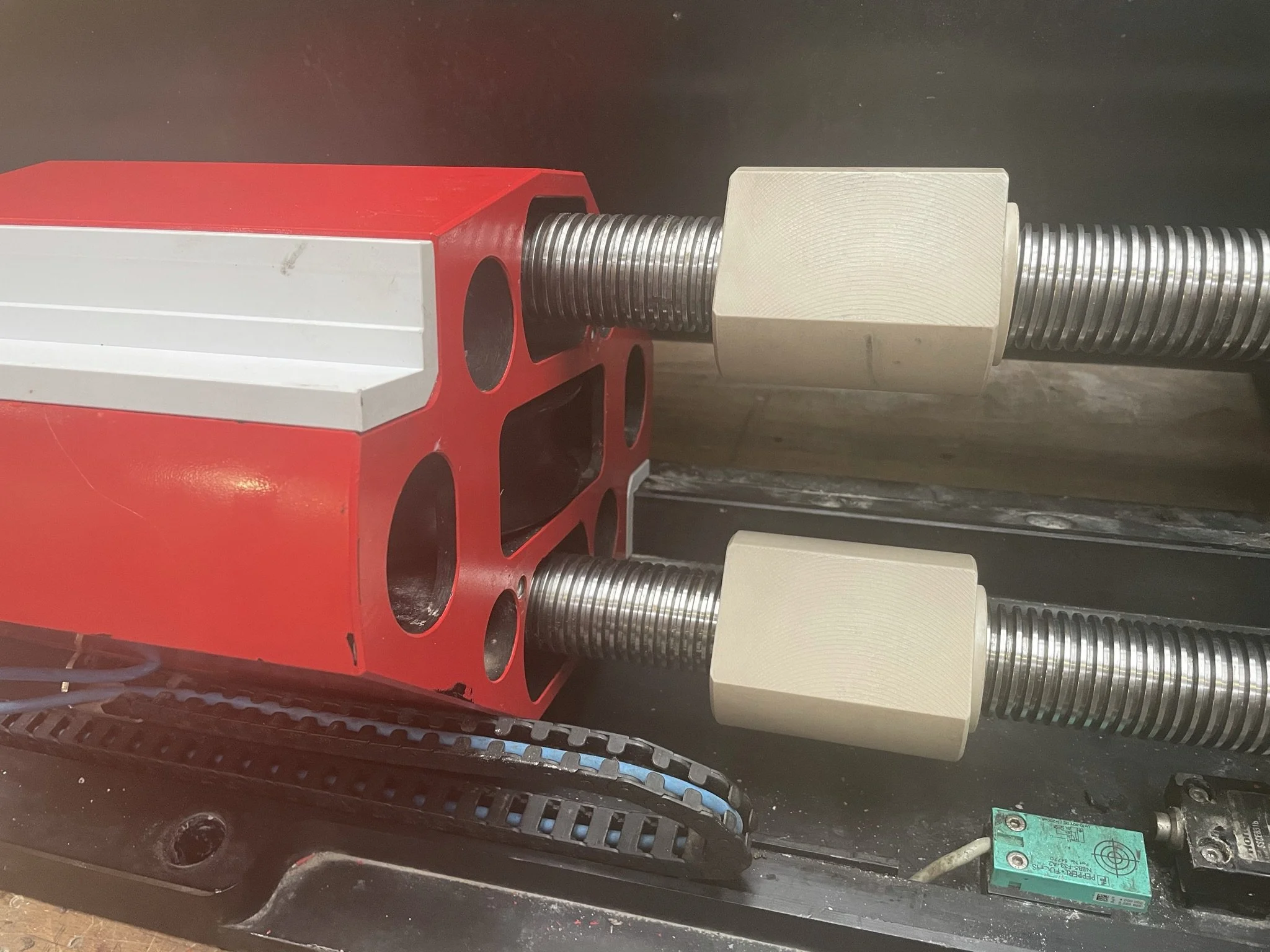

The Design of the Harken Captive is focused on requiring as little maintenance as possible, however an annual inspection is recommended. All parts connected to the hydraulic or electric circuitry, screw bearings and gear transmission are on the motor side of the winch for easy access. All bearings are sealed and lubricated with grease, the main gearbox is sealed and lubricated with Oil. The feeder Screw nut and feeder skate are made of self lubrication composite.

A annual Harken ProCare Service will include:

Check nut feeder nut alignment.

Check all Fastener tightness.

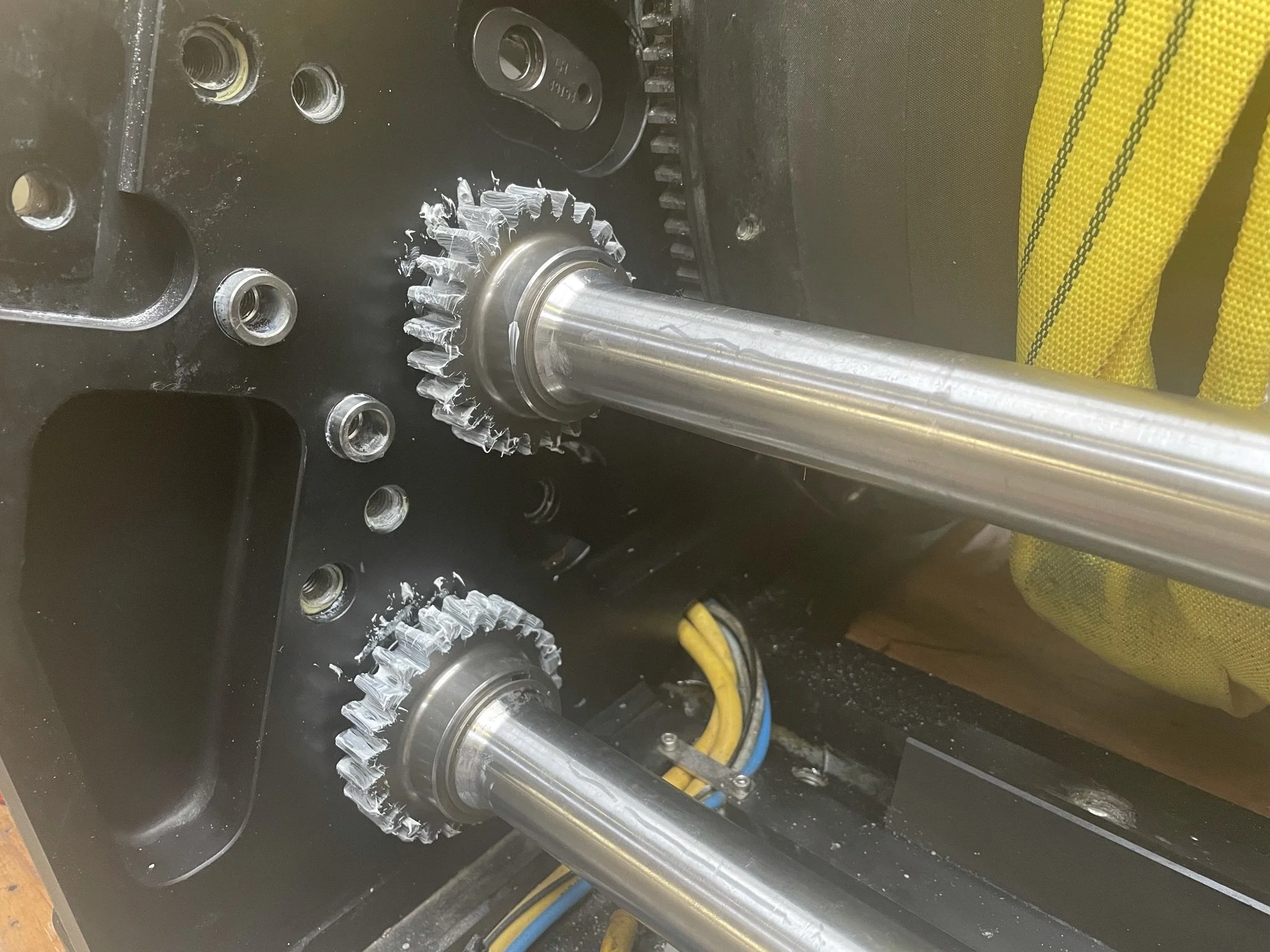

Verifying the condition of all transmission gears, clean and relubricating.

Verifying the condition of the Feeder Screw bearings, clean and relubrication.

Verify condition and wear level of feeder Nuts.

Verify condition and wear level of sliders.

Clean feeder Screw and base plate from dust, rope deposits and salt residue.

Check and verify all sensors are operating correctly.

Check all Hydraulic plumbing for signs of wear and damage.

Fully check operation of unit.

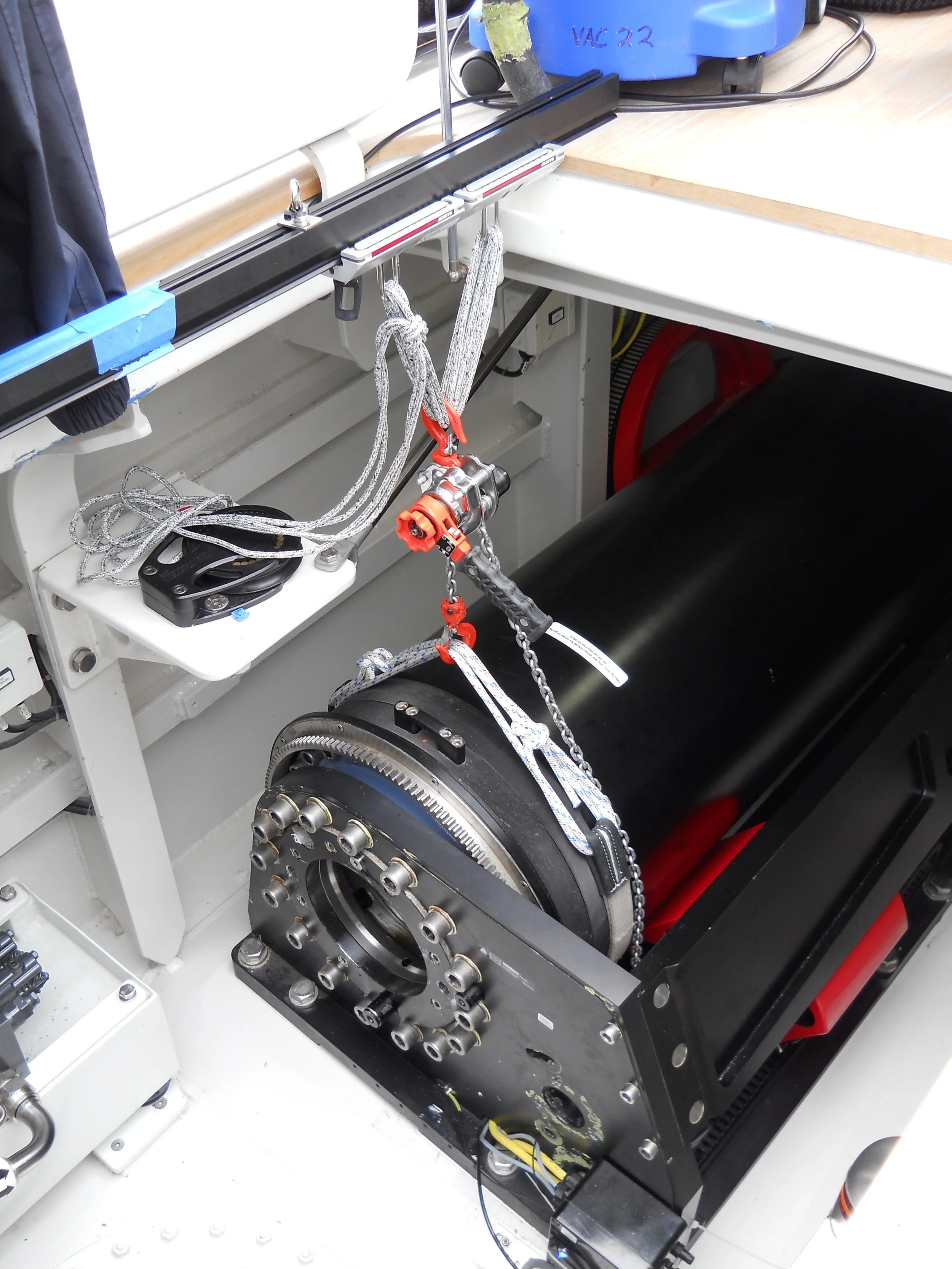

As these units are often located out of sight, the most important checks are the intricate safety systems installed with all Harken Captive Reel Winches. We recommend a Safety Check by the Harken ProCare Team annually.

CAPTIVE TENSIONER INSPECTION / SERVICE

The tensioner must be visually inspected at the beginning and end of every season of sailing or racing. After an inspection, replace worn or damaged components.

An annual Harken ProCare Service will include:

Full Disassembly of unit.

Re toque all fasteners and mark.

Reset tension of the belts

Clean and Grease transmission gears

Check the movement of the Tensioner sheave

Check pipe work for hydraulic leaks and hydraulic hoses for any signs of damage or chafing.

Replace all drive belts Annually.

HISTORY

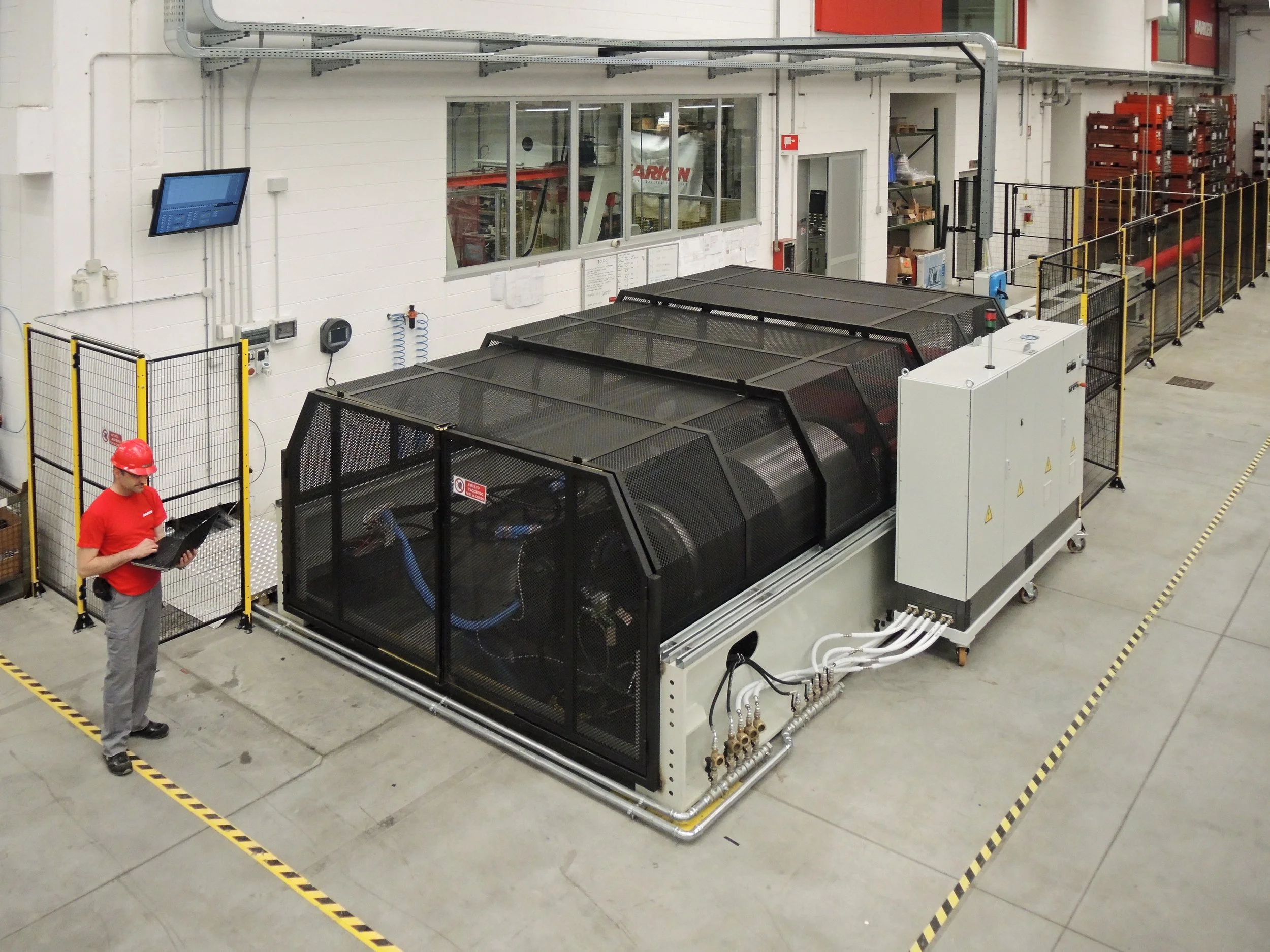

Harken Captive Reel winches represent a leap forward in captive winch design. The result of years of intense development at Harken Italy’s dedicated facility, captive winches are offered with pulling loads of 1.5 to 25 tons, with larger models currently under development. Winches are driven by a sealed inner motor gearbox, and are modular in construction for easy maintenance and service. Drum lengths vary to fit individual project requirements. Product not stocked. Contact Harken to request quote and lead time.

Harken has finished bench testing 70-ton (154,324 lb) hydraulic and electric prototypes designed for an upcoming new breed of "gigayachts" over 80 meters. The inclusion of the electric version is an unprecedented capability above the 20-ton range that can reduce noise, improve efficiency, and recharge the battery while easing.

"The capacity of these electric and hydraulic winches is incredible, New vessels will dwarf the already enormous loads seen on megayachts, so we wanted to be ready to lead the industry in the 40- to 70-ton range. Constant trimming in and out a few inches to play every gust while beating up a race course is normal on a dinghy or an AC boat. Now it's imaginable with a 70-ton load on the sheet.

"We invested in our largest test bench yet for this project," says Andrea Merello, Technical and Vice Managing Director of Harken Italy. "The 20-meter bench has a 100-ton load capacity for simulating a variety of blue water sailing conditions and long-term loading. Having a dedicated bench is crucial for custom projects because each component needs to be tested as part of the complete system when you're dealing with such extreme loads."

The design also features an innovative twin-screw inner transmission for faster trimming speeds, a smaller overall winch size, and reduced component wear-a vast improvement over current market offerings. Harken engineers also made major improvements in the tensioning system with a system that minimizes sheet wear by evenly gripping over a large surface area. The team plans further development of turnkey systems and cooperation with leading rope manufacturers.

Book Your Service now.................

Book Your Service now.................